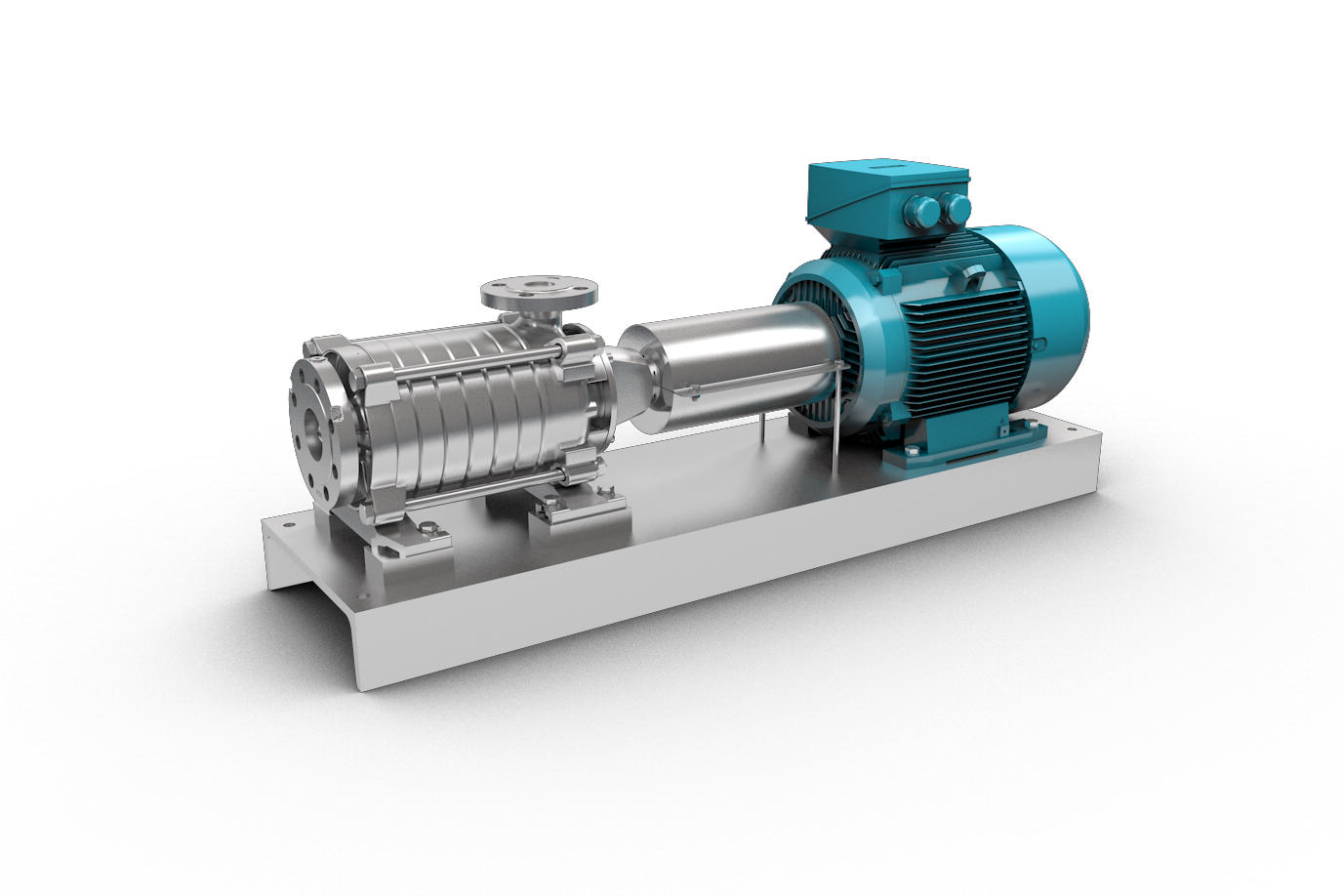

Liquefied Gas Pumps

LPG pump for the unloading of liquefied petroleum gas fuel, filling, transportation and filling process. The requirements of the pump pressure difference, gas-liquid mixing delivery, low cavitation margin, low pulse transmission, low noise emissions and ATEX explosion-proof demonstration. The user is also expected that the gas liquid mixture can be stable and reliable, and can control the change of the amount of gasification and steam pressure of the liquefied fuel, and the more reliable and efficient pump.

-

NHE

NHE

- Advantages

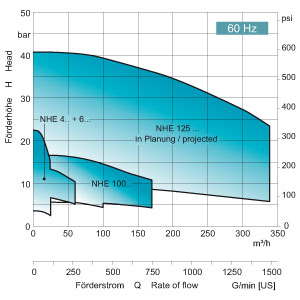

- Performance curves

- Technical Support

Advantages

|

◇High

energy-efficiency Very high efficiencies Optimized impeller approach flow Low internal friction losses Optimized head per stage ◇Easy maintenance Modular construction system for customized solutions Compact bloc- or bedplate design ◇Easy service ◇Application Operating pressure up to 40 bar Temperature -40℃ up to +110℃ Viscosity up to 115 mm2/s |

◇Technical

superiority Open impellers without axial trust or balanced closed impellers Compensation of radial forces by means of diffuser devices in the annular casing NPSH inducer stages Low noise emissions ATEX conformity Process reliability Partial gas supply Wide performance curve characteristics High pressure stages Low NPSH-values |